With state-of-the-art anesthesia machine, everyone’s sleeping better

A new, state-of-the art anesthesia machine has arrived on campus, and a lot of people are breathing a little easier.

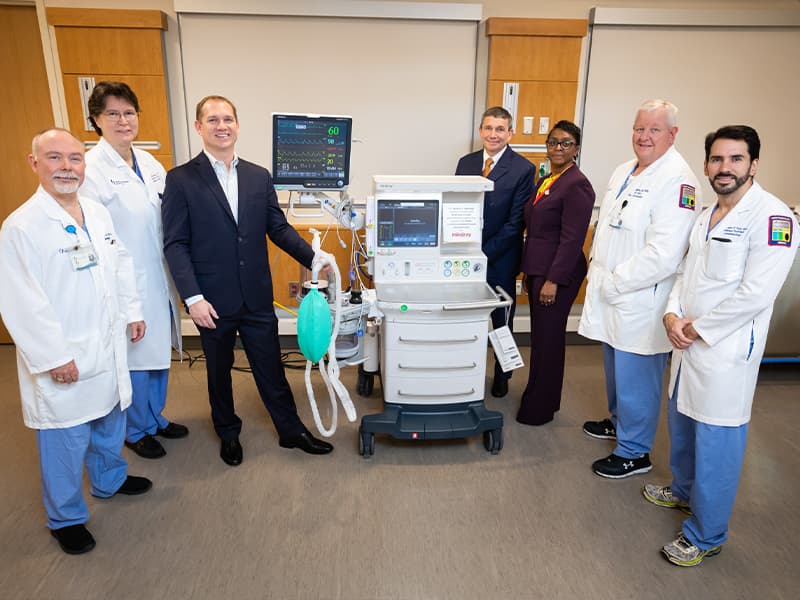

Accompanied by a monitor that pushes its total value as high as $80,000, it has been donated to the Simulation and Interprofessional Education Center, housed in the School of Medicine at the University of Mississippi Medical, where learners and professional caregivers alike can tap into its up-to-date features.

Delivered earlier this month by Mindray North America, a division of a world-wide manufacturer and supplier of medical devices, the apparatus was added to the SIEC’s inventory due to, in large part, the work and influence of Kenneth Rainey, associate chief of infrastructure in the Department of Anesthesiology.

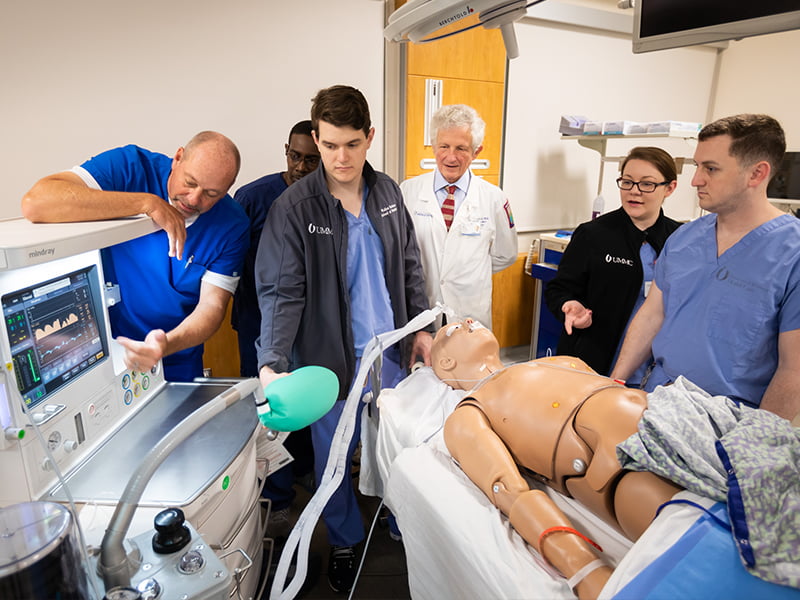

Its presence means trainees can undergo a more authentic operating room experience. “You practice more common procedures in the Simulation Center but also those you won’t see every day, in order to be better prepared when you do see them with actual patients,” said Rainey, a certified registered nurse anesthetist.

“Then you can take that knowledge with you in a real clinical setting, where you will be more ready to work.”

The new contrivance erases the gap between the actual OR experience and the simulated OR. The technology of its predecessor “was 15 years behind,” said Dr. Anna Lerant, professor of anesthesiology and the SIEC’S managing director.

“It has been a challenge for younger generations.”

All generations of health care professionals are embraced by the SIEC, whose missions is to teach patient-care skills with manikins and standardized patients, or patient actors, in a realistic medical setting.

“The beauty of the Simulation Center is you can play with a machine and not hurt anybody,” said Dr. Douglas Bacon, professor and chair of anesthesiology. “To give learners that chance is phenomenal.”

They are now learning on equipment weighing more than 400 pounds and whose appearance calls to mind an ATM mashed up with a medicine cabinet and a carburetor waving a balloon.

To the Simulation Center faculty and staff, it looks like a million bucks. Apparently, no one has ever donated equipment to the center before.

“It’s a first,” Rainey said.

Mindray North America’s gift, Lerant said, offers a leg up to the anesthesiology simulation team: Dr. Dan Castillo, professor of anesthesiology and chief of cardiac anesthesiology, and Dr. Henrique Vale, assistant professor of anesthesiology, as they design, and teach with, more credible OR scenarios.

Those who will benefit include the 38 anesthesiology residents, along with seven anesthesiology fellows, medical students, student registered nurse anesthetists, nursing students, nurse practitioners and, Lerant said, attending physicians striving to maintain their anesthesiology certification.

Rainey fattened that list. “Even people not training in anesthesiology or the OR are provided training in patient hemodynamic monitoring,” he said, referring to monitor’s display of a patient’s heart rate, blood pressure and more.

“There is also critical care and patient pulmonology, managing the patient’s lung mechanics.

“Those in disciplines that touch those [areas], which is virtually everything and everyone – including first responders, paramedics, and more – are given the opportunity to train on the machine. It’s part of the curriculum for just about everybody.”

Anesthesiology appliances popped up approximately the same year the Titanic went down, 1912. Their basic structure has not changed from that of a contraption developed in 1917, although strides in technology have made them safer and easier to use for the work they were put here on this earth to perform: preparing a gas mixture delivered to a breathing system for surgery patients.

So, if you’re going to drive a Tesla, you don’t want to learn on a Vespa.

“The OR setup at UMMC is very different from what was in the Simulation Center – until now,” Bacon said.

“With the new machine, the setup is now 99.9 percent similar to what residents will see in the actual OR and elsewhere in the Medical Center.”

That is, Rainey said, “cutting-edge machines that can handle the sickest patients with such critical needs as a heart transplant.”

The swapped-out version was at one time part of the Department of Anesthesiology’s stock. “Some years ago, it was upgraded and kept for use as a teaching tool,” Rainey said. “When the first simulation lab was created, it found a home there, and was in the Classroom Wing at one time.”

The tools of anesthesiology have advanced significantly in the past five years, never mind the past 15, Bacon said. “They are more precise. You have a much finer control over things.”

The subbed-out model is “a dinosaur,” Rainey said. With that in mind, he made his appeal to Mindray, a company that had already made its mark in the Medical Center.

“We had already bought 28 of their machines, about half of our inventory in the Medical Center,” Rainey said. “We’re looking at a long-term plan to phase out and standardize all anesthesia machines with this one model.

“When we first gave Mindray a shot to be a vendor, the equipment acquisition committee realized that this technology just simply blew every other product out of the water.”

Hoping for an opportunity to update the Simulation Center’s teaching tool, Lerant asked if there was an extra model was available, considering the phase-out. There was not. The Medical Center needs them all, Rainey said.

Instead, Rainey went to Mindray’s regional vice president. “I asked the company to donate a machine,” he said. “I said they would benefit, considering the number of people who will see it and who will learn on it. It would be free advertising.”

It worked.

“It’s not something we commonly do,” said Jeff Goethe, Mindray North America’s Dallas-based sales manager for the western half of the U.S.

“When we do, we see what a site has to offer. We look at what type of staff goes through the facility, what kind of exposure it has. And we understand that budgets are limited. We certainly want to help you guys out.”

The model, the Mindray A7, would sell on the retail market for about $50,000, Goethe said. It has a large, 15-inch touch screen display, compared to previous models’ three-inch-by-five-inch dimensions. The patient monitor adds another $15,000 to $30,000 to its value.

“It provides great visibility, and more information is displayed,” Goethe said. “It can be linked to electronic health records.” And it is safer for patients than earlier models.

“It’s a generous gesture,” Rainey said. “I’m thrilled that Mindray saw that we needed the best they had to offer.”